In reality the productivity issue is permanent in every corner of life, not only at businesses where it is engaged into productivity.

“If we want to increase productivity, quality, to make real Made in Vietnam products by technology and wisdom of Vietnamese people, we must first reduce waste. Because of the fact, the story of productivity is permanent in every corner of life, not only at businesses where it is engaged into productivity”.

Associate Prof. Nguyen Dang Minh spoke at the policy dialogue

This is an important part of Assoc. Dr. Nguyen Dang Minh – Chairman of the Advisory Council of GKM Lean Institute at the Policy Dialogue “INCREASING LABOR PRODUCTIVITY FOR VIETNAM” by the Institute of Vietnam Economic and Policy Research (VEPR), with support of Konrad Institute – Adenauer Stiftung (KAS) held on the morning of September 26, 2018.

The dialogue not only provides Vietnamese enterprises with a clear view of the panorama of Vietnam’s labor productivity. What have we done compared to history and where are we in the context of the current global market.

Since then, enterprises and experts to discuss to find solutions to the problem of improving labor productivity. Japan has done this after World War II as well as Singapore did in the early 1960s. And now, it’s our turn.

Overview of the policy dialogue

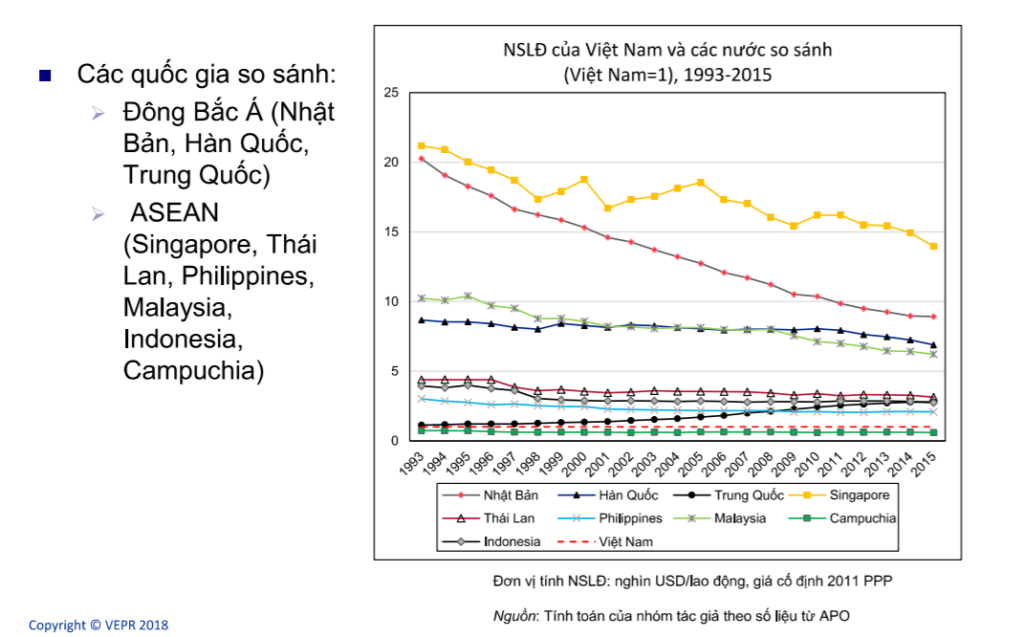

The dialogue frankly pointed out: Our country’s labor productivity is still low when compared to the average labor productivity of the world. Specifically, in 2017, our labor productivity is only half of that of low-middle income countries, and by 18.3% of the group of high average countries. It can be said, we are very difficult to catch up even the countries in the region like Japan, South Korea, China, Singapore, Thailand, Philippines, Malaysia and Cambodia.

Only by improving productivity, Vietnam can overcome the middle-income trap, restructure industries and participate in global value chains – experts at the dialogue session said.

Research results from the Institute of Vietnam Economic and Policy Research (VEPR) also show that changing to improve labor productivity depends not only on the capital intensity but also on fundamental changes in the thinking of how to organize life, organize activities and other related factors such as technological innovation, production rationalization, management improvement and etc.

Vietnamese labor productivity is comparable to other countries. Source: VEPR

At the dialogue, Assoc. Nguyen Dang Minh shared: Productivity and quality – two important factors of the market economy but in reality the increasing of productivity must come from thinking, must increase from the overall factors. The productivity issue must be permanent throughout the life areas. Any jobs must be productive, not only at businesses where it is engaged into productivity.

Enterprises in developed countries such as the US, Japan, Singapore … all apply lean management model in accordance with their practices (Made in USA lean management Made in Japan lean management, Made in Singapore lean management…) and Vietnam we have a Made in Vietnam Lean Management model (known as GKM Lean Management).

From evidence of results of the consulting successfully applied in the Vietnamese environment at Thaco Truong Hai Auto Corporation, Vietnam Paper Corporation (Bai Bang Paper), Vietnam Mineral Corporation Vimico (Luyen Dong) and etc. Assoc. Nguyen Dang Minh affirmed that Vietnamese people can fully use Made in Vietnam Lean Management to solve the problem of labor productivity.

Starting with a change of the thinking with the foundation of Tam The and lean thinking, we will form a healthy, neat lifestyle, eliminating waste in life itself.

Since then, it will contribute to eliminating waste in production as well as to improve production innovations, aiming at increasing labor productivity and sustainable development.

Thus, to increase labor productivity, basically, need to change from the thinking itself. Having a lean thinking not only life is more productive but also labor productivity and production will be also increased and more effective.

English

English