Hanoi, August 20, 2025, As part of her journey to explore the depth of the philosophy and practical application of the Made in Vietnam Finest Management Technology (QTTG MIV), Professor Chikako Hironaka, an Economics Professor at Chukyo University in Japan, embarked on a multi-day working visit to Vietnam. Invited by Assoc. Prof. Dr. Nguyễn Đăng Minh and GKM Vietnam, her visit aimed to examine a new-generation cooperation model between Vietnam and Japan based on this management technology, while also assessing its potential applicability in international contexts.

Prof. Chikako at the GKM Group office, holding the book “The Made in Vietnam Finest Management : From Philosophy Creation to Practical Implementation.” (Photo: GKM)

As of August 20, Professor Chikako had visited and worked with three exemplary Vietnamese enterprises currently applying the Made in Vietnam Finest Management Technology (QTTG MIV): Bảo Minh Confectionery Joint Stock Company, Windtech Vietnam Technology Joint Stock Company, and AMECC Construction Mechanical Joint Stock Company.

AT BẢO MINH: BREAKING THROUGH LIMITS

General Director Ngô Thị Tính shared the journey of implementing QTTG MIV at her company—a journey that initially faced significant challenges. With a workforce where many employees had only completed grade 7, transforming management thinking seemed nearly impossible. However, thanks to the gene system within the QTTG MIV Technology, the company was able to transform people from within: workers became managers of their own jobs. They understood the essence of their work, took initiative in execution, and became fully responsible for progress, quality, and productivity.

After nearly three years of applying QTTG MIV, Bảo Minh’s internal strength has exceeded conventional limits—not just in terms of annual revenue and profit, but also in its ability to grow even during off-seasons, which were once seen as an unavoidable weakness of the industry.

While sampling new R&D products at Bảo Minh, Professor Chikako expressed her astonishment at the profound transformation of the human workforce and recognized it as a human development model with the potential for international replication.

The delegation touring Bảo Minh’s factory. (Photo: GKM)

From left to right: Assoc. Prof. Dr. Nguyễn Đăng Minh, Prof. Chikako, General Director Ngô Thị Tính. (Photo: GKM)

Prof. Chikako standing beside a Vietnamese bronze drum in the lobby of Bảo Minh. (Photo: GKM)

The journey of Bảo Minh—from its formation and development to its aspiration to reach new heights—built upon the foundation of the Made in Vietnam Finest Management Technology. (Photo: GKM)

Bảo Minh’s 2025 Mid-Autumn Festival products received high praise from Prof. Chikako for both their content and presentation. (Photo: GKM)

AT WINDTECH: BILATERAL COOPERATION 2.0

At Windtech Vietnam Technology Joint Stock Company, General Director Đặng Anh Dũng had a candid discussion with Professor Chikako about the limitations of imported management models. He emphasized that with the foundation of Tâm Thế and the application of the Made in Vietnam Finest Management Technology (QTTG MIV), Vietnamese people are fully capable of taking over production lines and operational models currently lacking manpower in Japan.

When asked about potential support from the Vietnamese government, Mr. Dũng confidently stated:

“Within just five years, if this technology is robustly implemented, Vietnam will leap far ahead—potentially even surpassing some developed countries.”

He also highlighted the systemic nature of QTTG MIV: it is not merely about optimizing tools or processes, but about the holistic transformation of an organization—from mindset, language, and behavior to the operational system itself.

General Director Đặng Anh Dũng welcoming Prof. Chikako and Assoc. Prof. Dr. Nguyễn Đăng Minh at the entrance of Windtech Vietnam’s headquarters. (Photo: GKM)

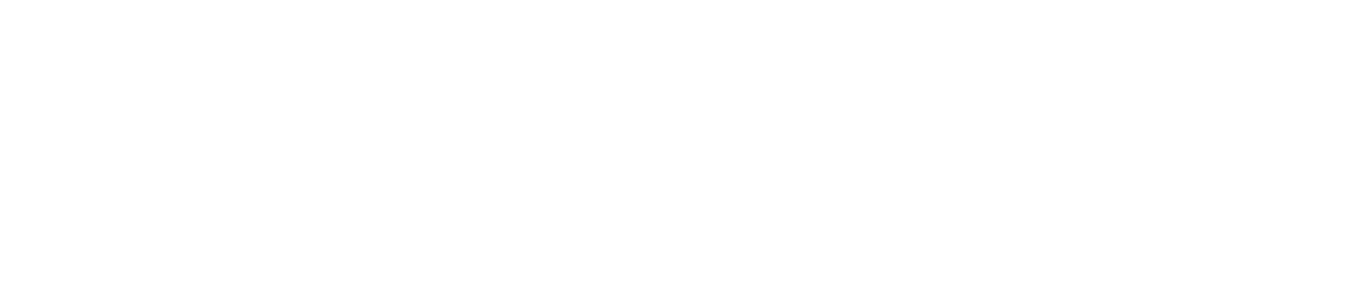

Prof. Chikako observed that the Made in Vietnam Finest Management board at Windtech features numerous methods for enhancing the overall capabilities of “work managers.” (Photo: GKM)

Chairman/General Director Đặng Anh Dũng and Deputy General Director Lê Thị Hưởng welcoming the delegation. (Photo: GKM)

AT AMECC: INTERGENERATIONAL EDUCATION BUILT ON A CONSISTENT GENE SYSTEM

On August 20, at AMECC Construction Mechanical Joint Stock Company, the GKM delegation and Professor Chikako were welcomed by General Director Nguyễn Văn Thọ and key department heads. She was guided on a comprehensive tour of the factory to witness firsthand the remarkable changes brought about by the application of the QTTG MIV technology, as well as to identify emerging challenges that GKM and Assoc. Prof. Dr. Nguyễn Đăng Minh could support and address in a timely manner.

What moved Professor Chikako most was the GKM Edu Summer 2025 Elite Education Program, designed for over 80 students—children of AMECC’s management team. The students were taught self-management, knowledge acquisition, and teamwork through a coherent educational program built upon the gene system of QTTG MIV Technology—the same platform on which their parents were also undergoing daily transformation at the company.

She noted that this was a rare example of intergenerational management education, with few parallels in the world.

Prof. Chikako expressed great interest in the QTTG MIV technology being implemented at AMECC, as presented by General Director Nguyễn Văn Thọ. (Photo: GKM)

AMECC maintains a close partnership with the Japanese company SANKYU, giving it deep insight into Japanese management practices in the Vietnamese context. (Photo: GKM)

The delegation toured AMECC’s factory, standing at the company’s main courtyard—a space that highlights the spirit of the “Five Standards” of the Made in Vietnam Finest Management Technology. (Photo: GKM)

THE ROLE OF THE CEO AND THE DISTINCTIVENESS OF THE MIV FINEST MANAGEMENT

Through multiple working sessions and firsthand observations at various enterprises, Professor Chikako Hironaka arrived at a clear conclusion: consistent, top-down leadership commitment from the CEO is a prerequisite for the Made in Vietnam Finest Management Technology (QTTG MIV) to be truly effective. This is not a one-off improvement model, nor is it an external solution to be applied from the outside. It demands alignment from the very roots—beginning with the mindset and Tâm Thế of the leader.

Professor Chikako also emphasized that unlike many common international consulting models—often implemented top-down and keeping internal processes hidden—QTTG MIV brings transparency to the entire journey of organizational transformation. Its consistency, proactivity, systematic approach, and GKM’s long-term companionship mark a significant difference. She affirmed:

“In Japan, there has never been a social science framework that is both so systematic, so highly practical, and so continuously validated as the QTTG MIV Technology.”

General Director Nguyễn Văn Thọ shared a profound insight when comparing QTTG MIV with traditional Japanese management styles. According to him, the Japanese model is known for its meticulousness and attention to detail. However, in the context of Vietnamese enterprises—where speed and flexibility are crucial for breakthroughs—this very cautiousness may become a barrier. In contrast, QTTG MIV, with its tightly structured gene system and the logic of the Five Standards, enables enterprises to be meticulous down to the smallest detail, while still maintaining the agility needed to avoid wasting valuable opportunities.

Mid-level managers at AMECC presenting the results of implementing QTTG MIV Technology to Prof. Chikako. (Photo: GKM)

Mid-level managers at AMECC presenting the outcomes of applying the QTTG MIV Technology to Prof. Chikako. (Photo: GKM)

Mr. Thọ emphasized:

“We do not accept delays under the guise of caution. QTTG MIV enables every individual at AMECC, in their specific roles, to embody the Tâm Thế of a manager—simultaneously overseeing quality, progress, productivity, safety, and cost.

This state of ownership can only be achieved when each person deeply understands how their work creates value for themselves. At AMECC, we apply Tâm Thế Management rigorously, in every department, every shift, every day. We maintain intense focus to ensure quality down to the smallest detail, while closely tracking actual progress against both the planned schedule and our ideal targets.

This is something we have never witnessed in any other model.”

TÂM THẾ AND KAIZEN: FOUNDATION AND TOOL

During the working session at AMECC, when asked about the relationship between “Good Tâm Thế” and Kaizen, Mr. Thọ explained:

“Good Tâm Thế is the foundation that allows Kaizen to function. Without a strong Tâm Thế, Kaizen cannot operate—no one identifies problems, no one improves, and worse, new problems may arise.”

Professor Chikako also inquired why the term Tâm Thế is not translated into English or Japanese. On behalf of Assoc. Prof. Dr. Nguyễn Đăng Minh, Mr. Thọ explained:

“We preserve the original term Tam The in all foreign-language documents not only to honor GKM’s intellectual property, but also because there is no word in any language that fully captures the essence of this concept. Just like Kaizen—the world uses the Japanese term as is because it carries a unique identity and core value.”

MÊ TRẦN AND SSP MOULDING: A FINEST ORGANIZATIONAL MODEL ROOTED IN TÂM THẾ AND INTERNAL CAPABILITY

On August 20, Professor Chikako Hironaka visited and held working sessions with entrepreneur Nguyễn Thế Hùng, Chairman of two companies: Mê Trần Bình Xuyên (specializing in high-tech electrical wires) and SSP Moulding (specializing in precision plastic molding).

Though not large-scale corporations, both enterprises made a powerful impression through their fine, efficient, and deeply thoughtful operations—built upon the foundation of the Made in Vietnam Finest Management Technology (QTTG MIV), developed by GKM.

The GKM delegation visiting SSP Moulding. (Photo: GKM)

Tâm Thế empowers enterprises to break through—from operational improvements to transformational management thinking.

During the meeting, Mr. Hùng presented the transformation journey that began in 2019, when the company officially integrated the power of Tâm Thế into its operating system. Thanks to this foundation, Mê Trần was able to overcome the COVID crisis with remarkable recovery speed and subsequently accelerated its growth in the following years. Revenue tripled compared to the starting point, while the workforce increased by only 1.5 times. Mr. Hùng shared that it was Tâm Thế that enabled him to understand and apply the Five Core Values, a foundational framework for realigning all management behaviors, from strategy down to each individual position. This is not theory, he emphasized, but a practical tool for reflection, one that helps leaders recognize a fundamental truth: human capability is the most critical resource, not the number of people or external tools.

Chairman Nguyễn Thế Hùng presenting to Prof. Chikako the differences observed before and after over five years of applying the QTTG MIV Technology. (Photo: GKM)

A FINEST ORGANIZATION THROUGH HUMAN TRANSFORMATION—WITHOUT REDUNDANT SUPERVISION

What impressed Professor Chikako most was not merely the growth indicators, but the organizational model itself. She noted that the company operates with 4–5 times fewer employees compared to other firms with similar machinery and product lines that she had seen. However, rather than sensing any shortfall, she recognized that this level of refinement originates from a fundamentally different management philosophy.

In most places, multiple layers of personnel are needed to supervise one another. But here, every employee is cultivated to become a “work manager”—capable of self-monitoring, self-correction, and continuous improvement. This transformation is the result of a structured training process built on the gene system of the QTTG MIV Technology, where workers are no longer mere executors, but managers who master their tasks, take ownership of their positions, and are accountable for quality.

Thanks to this, the company no longer needs a separate quality control department. The defect rate is nearly zero. Previously, assembly and inspection were two separate steps. Now, they are seamlessly integrated into one action, where the operator is also responsible for verifying quality. Small, continuous enhancements—initiated directly from the field—have helped eliminate redundant steps and procedures, reducing production time by more than 30%.

General Director Bùi Mạnh Tưởng added that the company maintains a notably low employee turnover rate, especially among frontline workers. This is because employees feel empowered, have clear direction, and find real meaning in their work—for themselves, for the company, and for society. The term “work manager” in QTTG MIV is not just a title; it represents a deeply rooted connection between individuals and the organization.

A HARMONIOUS DEVELOPMENT OF EFFICIENCY, HUMANITY, AND COMMUNITY

Beyond operational excellence, the two enterprises also invest significantly in human well-being. Meal programs have been upgraded to meet nutritional standards and are now run by in-house staff who voluntarily trained in culinary arts—replacing outsourced kitchen services.

Employee welfare has been expanded with the addition of a gym, sports fields, and a swimming pool. Notably, in the local area, public pools are scarce. This facility not only serves internal needs but also provides swimming lessons to the surrounding community—a socially meaningful contribution.

In terms of technology, the company has avoided dependency on external providers. Instead, it has built its own ERP system aligned with the QTTG MIV logic, ensuring that digital operations evolve in harmony with human capability—a challenge commonly seen in companies that adopt external software without a compatible management foundation.

At the same time, the company has obtained several prestigious international certifications such as DQS and ILAC-MRA, and has established an in-house laboratory to verify the quality of new products—proactively ensuring standards instead of waiting for customer feedback.

Prof. Chikako found the meeting at SSP Moulding particularly engaging, with many insightful exchanges. (Photo: GKM)

Chairman Nguyễn Thế Hùng offered a clear and powerful reflection:

“Many people think software will help a company operate better. But if the people aren’t ready, software is just a lifeless tool. The most valuable investment is in people—that is the true core capability of an enterprise.”

At the end of the visit, Professor Chikako Hironaka affirmed that with the Bilateral Cooperation Model 2.0 built on the QTTG MIV foundation, Vietnam has already proven its capability—not as a distant aspiration, but as a clear and present reality.

Not through slogans or declarations, but through concrete performance indicators, streamlined production lines, humble yet empowered individuals, and an organizational spirit rooted from the very core: Tâm Thế.

🎉A Heartfelt Moment, Deeply Imbued with the Spirit of Made by VietnamDuring lunch at Windtech that day, there was a simple yet touching moment that brought smiles to everyone present: General Director Đặng Anh Dũng and his young son peeled a custard apple together to offer to Professor Chikako. It was more than just an expression of Vietnamese hospitality, it was a vivid symbol of the “shared gene” spirit, where not only the enterprise but the entire family lives, learns, and spreads the values of the Made in Vietnam Finest Management Technology. |

|

English

English